Laser surface jiyya wata fasaha ce da ke amfani da babban iko yawa Laser katako don dumama saman kayan a cikin wani mara lamba hanya, da kuma gane ta surface gyare-gyare ta hanyar conductive sanyaya na kayan saman da kanta.Yana da amfani don inganta kayan aikin injiniya da na jiki na kayan abu, da kuma juriya na lalacewa, juriya na lalata da juriya na gajiyar sassan.A cikin 'yan shekarun nan, Laser surface jiyya fasahar kamar Laser tsaftacewa, Laser quenching, Laser alloying, Laser girgiza ƙarfafawa da Laser annealing, kazalika da Laser cladding, Laser 3D bugu, Laser electroplating da sauran Laser ƙari masana'antu fasahar sun kawo a m aikace-aikace bege. .

1. Laser tsaftacewa

Tsabtace Laser sabon fasaha mai haɓakawa ne mai saurin haɓakawa, wanda ke amfani da katako mai ƙarfi na bugun jini na Laser don haskaka saman kayan aikin, ta yadda datti, barbashi ko shafi akan saman na iya ƙafe ko faɗaɗa nan take, don haka cimma aikin tsaftacewa. da tsarkakewa.Laser tsaftacewa ne yafi raba tsatsa kau, man kau, fenti kau, shafi kau da sauran matakai;An yafi amfani da karfe tsaftacewa, al'adu relics tsaftacewa, gine-gine tsaftacewa, da dai sauransu Bisa ga m ayyuka, daidai da m aiki, high dace da makamashi ceto, kore muhalli kariya, babu lalacewa ga substrate, hankali, mai kyau tsaftacewa quality. aminci, fadi da aikace-aikace da sauran halaye da kuma abũbuwan amfãni, ya zama ƙara rare a daban-daban masana'antu filayen.

Idan aka kwatanta da gargajiya tsaftacewa hanyoyin kamar inji gogayya tsaftacewa, sinadaran lalata tsaftacewa, ruwa m karfi tasiri tsaftacewa, high-mita ultrasonic tsaftacewa, Laser tsaftacewa yana da fili abũbuwan amfãni.

2. Laser quenching

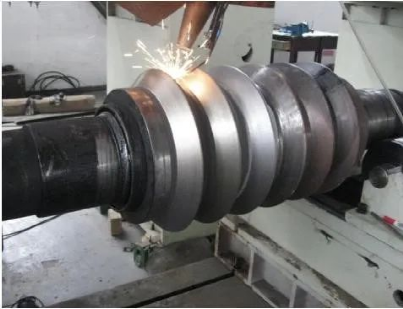

Laser quenching yana amfani da Laser mai ƙarfi a matsayin tushen zafi don sanya saman karfe yayi zafi da sanyi cikin sauri.Ana kammala aikin kashewa nan take don samun babban taurin da ultra-lafiya martensite tsarin, inganta taurin da kuma sa juriya na karfe saman, da kuma samar da matsa lamba a saman don inganta gajiya juriya.Babban fa'idodin wannan tsari sun haɗa da ƙaramin yanki da zafi ya shafa, ƙaramin nakasawa, babban matakin sarrafa kansa, kyakkyawan sassaucin zaɓin zaɓi, babban taurin hatsi mai ladabi, da kariyar muhalli mai hankali.Misali, ana iya daidaita tabo na laser don kashe kowane matsayi mai faɗi;Na biyu, shugaban Laser da haɗin gwiwar mutum-mutumi na axis na iya kashe yankin da aka keɓance na sassan sassa.Ga wani misali, Laser quenching yana da zafi sosai da sauri, kuma quenching danniya da nakasawa kadan ne.The nakasawa na workpiece kafin da kuma bayan Laser quenching za a iya kusan watsi, don haka shi ne musamman dace da surface jiyya na sassa da high ainihin bukatun.

A halin yanzu, Laser quenching da aka samu nasarar amfani da surface ƙarfafa na m sassa a cikin mota masana'antu, mold masana'antu, hardware kayan aikin da inji masana'antu, musamman a inganta da sabis rayuwa na m sassa kamar gears, shaft saman, jagororin, jaws da kuma kyawon tsayuwa.Halayen Laser quenching sune kamar haka:

(1) Laser quenching ne mai sauri dumama da kai m sanyaya tsari, wanda ba ya bukatar tanderun adana da coolant quenching.Yana da tsari mara ƙazanta, kore da muhalli-friendly magani tsari, kuma zai iya sauƙi aiwatar da uniform quenching a saman manyan molds;

(2) Yayin da saurin dumama Laser ɗin ke da sauri, yankin da zafin ya shafa ƙanƙanta ne, kuma yanayin zafi yana kashe wuta, wato, kashe dumama na gida nan take, nakasar wanda aka yi masa magani kaɗan ne;

(3) Saboda ƙananan bambance-bambancen kusurwa na katako na Laser, yana da kyakkyawan jagoranci, kuma yana iya daidaitaccen wuri na kashe ƙera ta hanyar tsarin jagorar haske;

(4) Zurfin zurfin Layer na Laser saman quenching shine gabaɗaya 0.3-1.5 mm.

3. Laser annealing

Laser annealing tsari ne na maganin zafi wanda ke amfani da Laser don dumama saman kayan, fallasa kayan zuwa yanayin zafi na dogon lokaci, sannan a hankali kwantar da shi.Babban manufar wannan tsari shine don saki danniya, ƙara yawan ductility da tauri, da kuma samar da microstructure na musamman.An kwatanta shi da ikon daidaita tsarin matrix, rage taurin, tsaftace hatsi da kawar da damuwa na ciki.A cikin 'yan shekarun nan, Laser annealing fasahar ya kuma zama wani sabon tsari a semiconductor sarrafa masana'antu, wanda zai iya ƙwarai inganta hadewa hadedde da'irori.

4. Ƙarfafa girgiza Laser

Fasahar ƙarfafa girgiza Laser sabuwar fasaha ce mai girma wacce ke amfani da igiyar girgizar plasma da aka haifar da katako mai ƙarfi na Laser don haɓaka ƙarfin gajiya, juriya da juriya na kayan ƙarfe.Yana da fa'idodi da yawa da yawa, kamar babu yankin da zafi ya shafa, ingantaccen ƙarfin kuzari, ƙimar matsanancin ƙarfi, ƙarfi mai ƙarfi da tasirin ƙarfafawa na ban mamaki.A lokaci guda, Laser shock ƙarfafa yana da halaye na zurfin saura matsa lamba danniya, mafi microstructure da surface mutunci, mafi thermal kwanciyar hankali da kuma tsawon rai.A cikin 'yan shekarun nan, wannan fasaha ta sami ci gaba cikin sauri, kuma tana da rawar gani a sararin samaniya, tsaro na kasa da na soja da sauran fannoni.Bugu da kari, da shafi ne yafi amfani don kare workpiece daga Laser konewa da kuma inganta sha na Laser makamashi.A halin yanzu, kayan shafa da aka saba amfani da su sune baƙar fata da foil na aluminum.

Laser peening (LP), wanda kuma aka sani da Laser shock peening (LSP), wani tsari ne da aka yi amfani da shi a fagen injiniyan saman, wato, yin amfani da katako mai ƙarfi na Laser don haifar da damuwa a cikin kayan don inganta juriya na lalacewa. (kamar juriya da juriya na gajiya) na saman kayan, ko don haɓaka ƙarfin sassan siraran kayan don haɓaka taurin saman kayan.

Ba kamar yawancin aikace-aikacen sarrafa kayan aiki ba, LSP baya amfani da wutar lantarki don maganin zafi don cimma sakamakon da ake so, amma yana amfani da tasirin katako don sarrafa injina.High iko Laser katako da ake amfani da tasiri a saman da manufa workpiece tare da babban iko short bugun jini.

Hasken hasken yana tasiri kayan aikin ƙarfe, yana vaporize da workpiece zuwa wani siraren jini na jini nan da nan, kuma yana amfani da matsa lamba mai girgiza ga aikin.Wani lokaci ana ƙara ɗan ƙaramin bakin ciki na kayan rufe fuska a cikin kayan aikin don maye gurbin ƙawancen ƙarfe.Don matsawa, ana amfani da wasu kayan rufewa na zahiri ko yadudduka na tsangwama don ɗaukar jini (yawanci ruwa).

Plasma yana haifar da tasirin girgiza, yana sake fasalin microstructure na saman kayan aiki a wurin tasiri, sannan ya haifar da sarkar haɓakar haɓakar ƙarfe da matsawa.Danniya mai zurfi da aka haifar da wannan dauki zai iya tsawaita rayuwar bangaren.

5. Laser alloying

Laser alloying wani sabon surface gyare-gyare fasaha, wanda za a iya amfani da shirya amorphous nanocrystalline ƙarfafa cermet hada coatings a saman tsarin sassa bisa ga daban-daban sabis yanayi na jirgin sama kayan da kuma halaye na high makamashi yawa Laser katako dumama da condensation kudi, don haka don cimma manufar gyaran gyare-gyaren kayan aikin jirgin sama.Idan aka kwatanta da Laser alloying fasahar, Laser cladding fasaha yana da halaye na kananan dilution rabo na substrate zuwa narkakkun pool, kananan zafi shafi yankin, kananan thermal nakasawa na workpiece da kananan scrap kudi na workpiece bayan Laser cladding magani.Laser cladding zai iya inganta yanayin saman kayan, da gyara kayan da aka sawa.Yana yana da halaye na high dace, azumi gudun, kore muhalli kariya da kuma gurbatawa-free, da kuma mai kyau yi na workpiece bayan jiyya.

Fasaha cladding Laser shima ɗayan sabbin fasahohin gyaran ƙasa ne wanda ke wakiltar alkiblar ci gaba da matakin injiniyan saman.Laser cladding fasahar ya zama wani bincike hotspot a saman gyare-gyare na titanium gami saboda da abũbuwan amfãni daga gurbatawa-free da karfe hade tsakanin shafi da substrate.Laser cladding yumbu shafi ko yumbu barbashi ƙarfafa hade shafi ne mai tasiri hanya don inganta surface lalacewa juriya na titanium gami.Dangane da ainihin yanayin aiki, zaɓi tsarin kayan da ya dace, kuma fasahar cladding laser na iya cimma mafi kyawun buƙatun tsari.Fasahar cladding Laser na iya gyara sassa daban-daban da suka gaza, kamar ruwan injin injin.

Bambanci tsakanin Laser surface alloying da Laser surface cladding shi ne cewa Laser surface alloying ne don cikakken Mix da kara gami abubuwa da surface Layer na substrate a cikin ruwa jihar samar da wani alloying Layer;Laser surface cladding shi ne ya narke duk precoating da micro narke da substrate surface, sabõda haka, cladding Layer da substrate abu samar da wani karfe hade da kiyaye abun da ke ciki na cladding m canzawa.Laser alloying da Laser cladding fasahar ana amfani da yafi don inganta surface lalacewa juriya, lalata juriya da grading juriya na titanium gami.

A halin yanzu, fasahar cladding Laser an yi amfani da shi sosai wajen gyarawa da gyare-gyaren filayen ƙarfe.Duk da haka, ko da yake gargajiya Laser cladding yana da abũbuwan amfãni da kuma halaye na m aiki, na musamman-dimbin gyare-gyare, mai amfani-tsare ƙari, da dai sauransu, da aiki yadda ya dace ne low, kuma shi har yanzu ba zai iya saduwa da bukatun na manyan-sikelin m samar da aiki a cikin. wasu filayen samarwa.Domin saduwa da buƙatun samar da taro da kuma inganta haɓakar haɓaka, fasahar cladding Laser mai sauri ta zo.

Fasahar cladding Laser mai saurin gudu na iya gane ƙaƙƙarfan Layer cladding kyauta.Ingancin farfajiyar cladding ɗin yana da ɗanɗano, haɗin ƙarfe na ƙarfe tare da ma'auni, ba buɗaɗɗen lahani, kuma saman yana da santsi.Ba za a iya sarrafa shi kawai a kan jikin mai juyayi ba, har ma a kan jirgin sama da kuma hadaddun farfajiya.Ta hanyar ci gaba da inganta fasaha, ana iya amfani da wannan fasaha sosai a cikin kwal, ƙarfe, dandamali na teku, yin takarda, kayan aikin jama'a, motoci, jiragen ruwa, man fetur, masana'antun sararin samaniya, kuma ya zama tsarin sake ƙera koren wanda zai iya maye gurbin fasahar lantarki ta gargajiya.

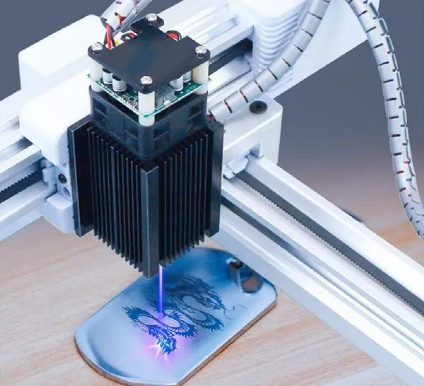

7. Laser engraving

Laser engraving tsari ne na sarrafa Laser wanda ke amfani da fasahar CNC don aiwatar da katako mai ƙarfi na Laser a saman kayan, kuma yana amfani da tasirin zafi da Laser ke samarwa don samar da fayyace alamu akan saman kayan.The jiki denaturation na narkewa da gasification na aiki kayan a karkashin hasken wuta na Laser engraving iya taimaka Laser engraving cimma aiki dalilai.Zanen Laser shine a yi amfani da Laser don sassaƙa kalmomi akan abu.Kalmomin da aka zana da wannan fasaha ba su da laƙabi, saman abin yana da santsi da lebur, kuma rubutun hannu ba za a sa ba.Siffofinsa da fa'idodinsa sun haɗa da: aminci kuma abin dogaro;Madaidaici kuma mai mahimmanci, madaidaicin zai iya kaiwa 0.02mm;Ajiye kariyar muhalli da kayan aiki yayin sarrafawa;Babban saurin gudu, zane-zane mai sauri bisa ga zane-zanen fitarwa;Ƙananan farashi, ba'a iyakance ta hanyar sarrafawa ba, da dai sauransu.

8. Laser 3D bugu

Tsarin yana ɗaukar fasahar cladding Laser, wanda ke amfani da Laser don haskaka kwararar foda da bututun ƙarfe ke ɗauka don narkar da abu mai sauƙi ko foda.Bayan da katako na Laser ya fita, gami da ruwa yana ƙarfafa da sauri don gane saurin samfurin gami.A halin yanzu, an yi amfani da shi sosai a cikin ƙirar masana'antu, masana'antar injina, sararin samaniya, soja, gine-gine, fim da talabijin, kayan aikin gida, masana'antar haske, likitanci, ilimin kimiya na kayan tarihi, al'adu da fasaha, sassaka, kayan ado da sauran fannoni.

9. Hankula masana'antu aikace-aikace na Laser surface jiyya da remanufacturing

A halin yanzu, Laser surface jiyya da ƙari masana'antu fasahar, matakai da kayan aiki da ake amfani da ko'ina a karafa, ma'adinai inji, molds, man fetur ikon, hardware kayan aikin, dogo sufuri, jirgin sama, inji da sauran masana'antu.

10. Aikace-aikace na Laser electroplating fasahar

Laser electroplating sabuwar fasaha ce mai amfani da wutar lantarki mai ƙarfi, wanda ke da mahimmanci ga samarwa da gyara na'urorin microelectronic da manyan da'irori masu haɗaka.A halin yanzu, duk da cewa ka'idar Laser electroplating, Laser ablation, plasma Laser deposition da Laser jet har yanzu suna kan bincike, an yi amfani da fasahar su.Lokacin da ci gaba da Laser ko bugun bugun jini yana haskakawa saman cathode a cikin wanka na lantarki, ba wai kawai za a iya inganta yawan adadin ƙarfe ba, amma kuma ana iya amfani da kwamfutar don sarrafa yanayin katako na Laser don samun rufin da ba a rufe ba. hadaddun lissafin lissafi da ake tsammani.

Aikace-aikacen Laser electroplating a aikace yana dogara ne akan halaye biyu masu zuwa:

(1) Gudun da ke cikin yankin hasken wuta na Laser ya fi girma fiye da saurin lantarki a cikin jiki (kimanin sau 103);

(2) Ƙarfin sarrafawa na Laser yana da ƙarfi, wanda zai iya sa sashin da ya dace na kayan ya haifar da adadin ƙarfe da ake bukata.Electroplating na yau da kullun yana faruwa akan dukkan nau'ikan lantarki, kuma saurin electroplating yana jinkirin, don haka yana da wahala a samar da sifofi masu rikitarwa da kyau.Laser electroplating zai iya daidaita katakon Laser zuwa girman micrometer, da gudanar da bincike mara kariya akan girman micrometer.Don ƙirar da'ira, gyare-gyaren kewayawa da ajiyar gida akan abubuwan haɗin haɗin microelectronic, irin wannan taswira mai sauri yana ƙara zama mai amfani.

Idan aka kwatanta da talakawa electroplating, da abũbuwan amfãni su ne:

(1) Saurin ajiya mai sauri, kamar Laser plating har zuwa 1 μ M / s, Laser plating har zuwa 10 μ M / s, Laser jet zinariya plating har zuwa 12 μ M / s, Laser jet jan karfe plating har zuwa 50 μ m/s;

(2) Ƙarfe na ƙarfe yana faruwa ne kawai a cikin yankin hasken wuta na Laser, kuma ana iya samun suturar ƙira ta gida ba tare da matakan kariya ba, don haka sauƙaƙe tsarin samarwa;

(3) Adhesion shafi yana inganta sosai;

(4) Mai sauƙin gane sarrafawa ta atomatik;

(5) Ajiye karafa masu daraja;

(6) Ajiye zuba jari na kayan aiki da lokacin sarrafawa.

Lokacin da ci gaba da Laser ko Laser turushi ya haskaka saman cathode a cikin wanka na lantarki, ba wai kawai za a iya inganta yawan adadin ƙarfe ba, har ma kwamfutar za ta iya sarrafa hanyar motsi na katako na Laser don samun suturar da ba ta da kariya tare da hadaddun da ake sa ran. ilimin lissafi.Sabuwar fasahar zamani ta Laser jet inganta electroplating hade da Laser inganta electroplating fasahar tare da electroplating bayani spraying, sabõda haka, Laser da plating bayani iya lokaci guda harba zuwa cathode surface, da taro canja wurin gudun ne da sauri sauri fiye da taro canja wurin gudun. na micro stirring lalacewa ta hanyar Laser sakawa a iska mai guba, don haka cimma wani sosai high ajiya gudun.

Ci gaba da haɓakawa na gaba

A nan gaba, da ci gaban shugabanci na Laser surface jiyya da ƙari masana'antu kayan aiki za a iya taƙaita kamar haka:

· Babban inganci - babban aiki yadda ya dace, saduwa da saurin samar da sauri na masana'antar zamani;

· Babban aiki - kayan aiki yana da ayyuka daban-daban, aikin kwanciyar hankali kuma ya dace da yanayin aiki daban-daban;

Babban hankali - matakin hankali yana inganta koyaushe, tare da ƙarancin sa hannun hannu;

· Ƙananan farashi - farashin kayan aiki yana iya sarrafawa, kuma an rage farashin kayan aiki;

Keɓancewa - keɓance kayan aiki na keɓaɓɓen, daidaitaccen sabis na tallace-tallace,

· Kuma hadawa - hada fasahar laser tare da fasahar sarrafa kayan gargajiya.

Lokacin aikawa: Satumba-17-2022