Tsarin Tsara don Laser Brazing

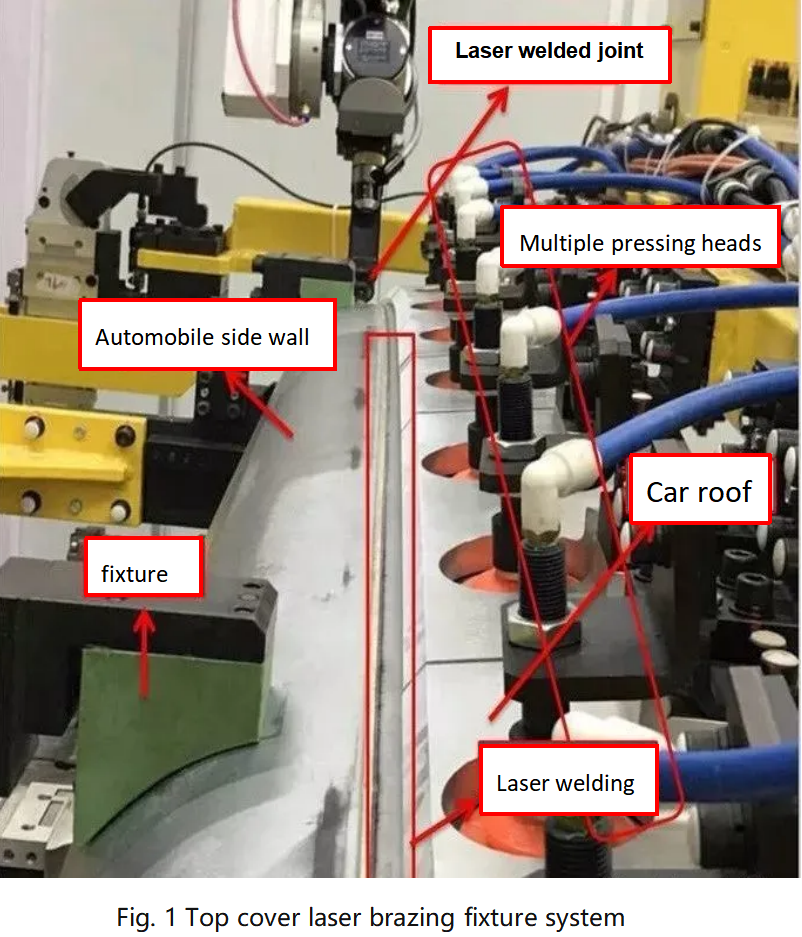

A lokacin waldawar Laser, wajibi ne a danne farantin karfen da aka welded da kyau sosai, don haka za a ƙera maƙalai na musamman.Ƙwararren walda na Laser yana da girma mai girma da kuma tsarin tsari.Tsarin firam ne gaba ɗaya.Hannun hagu da dama na jikin abin hawa suna da goyan bayan tubalan gyarawa kuma an matse su ta silinda bayan sanyawa da goyan baya.An tsara sashi na sama tare da matsayi na musamman da matsi mai matsi don laser brazing na rufin mota, wanda aka danna tare da matsi da yawa.Robot ɗin ya ɗauki rufin, ya sanya shi a jiki, sannan ya maƙale shi da silinda, ta yadda gefan farantin karfen jikin da za a yi walda ya yi daidai sosai.Kamar yadda aka nuna a hoto 1.

Abubuwan tsari

• Zazzabi

• kusurwar abin da ya faru na katako na Laser

• Tari da karkatar da hankali

• · zurfin shigar waldi

• Sakamakon saurin waldawa akan ƙarfin waldawar laser

Gwaji

• Duban gani

• · Bisa ga ma'auni na Jamusanci PV 6917 (ana iya samuwa ta hanyar tuntuɓar marubucin);

• · Za a gudanar da duban gani ga kowane yanki na waje;

• Mayar da hankali kan gano shigar walda (kamar shigar da ba ta cika ba, sama da shigar ciki da ƙonewa), da la'akari da yanayin walda (kamar spatter da porosity);

Hanyar kimantawa na Laser brazing dubawa na gani yana nunawa a cikin Table 1.

| Tebu 1 Ƙimar Ingantacciyar Fitowar Laser Brazing | ||

| Serial No | Bayanin lahani | Ƙimar ƙima |

| 1 | Bayyanar pores | Idan yanayi ya ba da izini, za a iya gyara saman idan dai bai shafi aikin ba;Dole ne a gyara ramukan iska mai diamita sama da 0.2mm |

| 2 | Ruwan solder (yawan yawa) | Idan yanayi ya ba da izini, za a iya gyara saman idan dai bai shafi aikin ba;Ana iya gyarawa |

| 3 | Layer ripple a kan weld surface | Dole ne a cika haɗin gwiwa tare da solder ci gaba;Ana iya gyarawa |

| 4 | Tsagewar saman (mai juyawa da tsayi) suna faruwa a walda | Idan yanayi ya ba da izini, za a iya gyara saman idan dai bai shafi aikin ba;Ana iya gyarawa |

| 5 | Tsagewar saman (mai juyawa da tsayi) suna faruwa a gindin karfe | Rashin cancanta, yana buƙatar gyara |

| 6 | Tushen ƙarfe shiga | Rashin cancanta, yana buƙatar gyara |

| 7 | Ƙarƙashin yankewa da shigar da bai cika ba | Rashin cancanta, yana buƙatar gyara |

| 8 | fantsama | Idan yanayi ya ba da izini, za a iya gyara saman idan dai bai shafi aikin ba;Ana iya gyarawa |

| 9 | Mara nama | Ba a yarda ba, ana buƙatar gyara |

| 10 | Ƙarshen farawa ba a walda shi ba, kuma tashar tasha tana rami | Ba a yarda ba, ana buƙatar gyara |

| 11 | Weld ya ɓace (babban rata mai daidaitawa) | Ba a yarda ba, ana buƙatar gyara |

2. Duban lalacewa

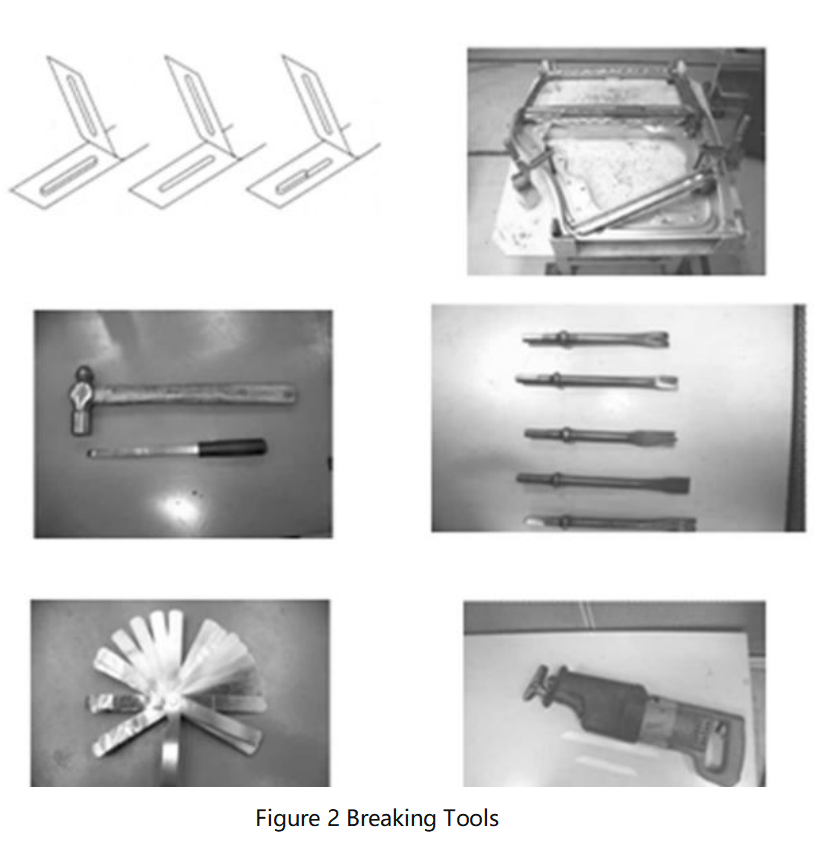

Ana nuna kayan aikin binciken ɓarna a cikin hoto 2:

3 、 Metallographic Microscopic Analysis

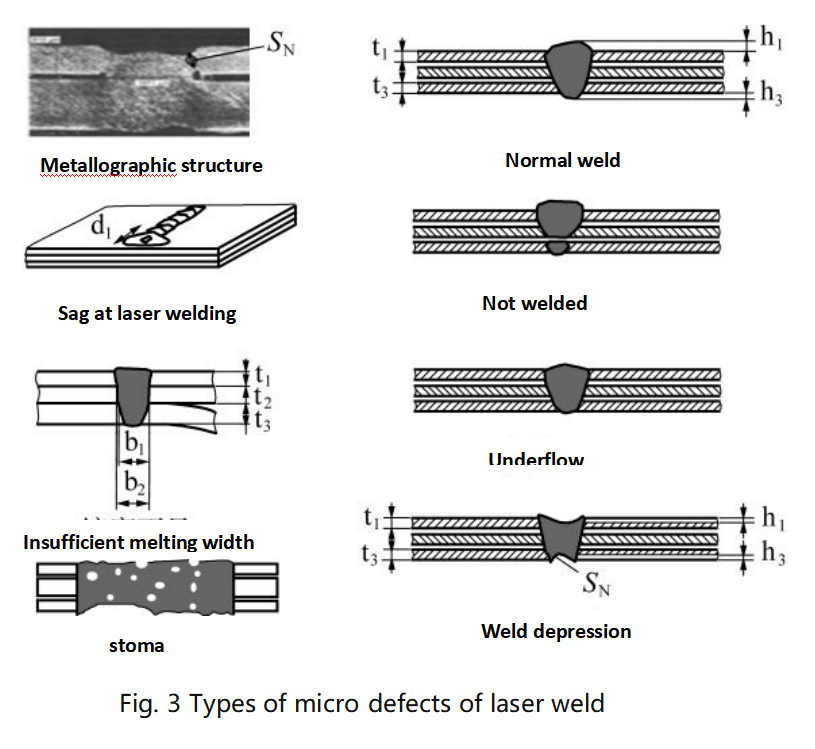

Ana nuna nau'ikan ƙananan lahani na walda laser a cikin hoto 3:

4, NDT

Ultrasonic, X-ray da sauran kayan aiki za a iya amfani da su duba ingancin walda Laser.

Takaitawa

Dangane da ainihin sakamakon aikace-aikacen fasaha na walda Laser a cikin tsire-tsire na motoci, ana iya ganin cewa walƙar laser ba kawai zai iya rage nauyin jikin abin hawa ba, inganta daidaiton haɗuwa da jikin abin hawa, amma kuma yana haɓaka ƙarfin abin hawa. jiki, samar da masu amfani da mafi kyawun tsaro yayin jin daɗin jin daɗi.An yi imani da cewa tare da ci gaba da nasara na Laser waldi fasaha matsaloli da kuma ci gaba da inganta masana'antu tsari, Laser waldi zai zama wani muhimmin ɓangare na nan gaba mota jiki a farin masana'antu tsari.

Lokacin aikawa: Janairu-09-2023