Gabatar da hanyoyin waldawa filastik Laser guda biyar

A cikin 'yan shekarun nan, tare da ci gaba da haɓaka fasahar fasaha, waldar laser na robobi a hankali zai nuna haɓakar haɓaka a nan gaba.A cikin 'yan shekarun da suka gabata, wasu fasahohin laser ba su karya ba, kuma farashin Laser yana da inganci.Idan aka kwatanta da walda na gargajiya, jarin lokaci ɗaya yana da yawa, wanda bazai haifar da fa'ida cikin sauri ba.Amma yanzu an nuna fa'idar tattalin arziki na Laser.Walƙar Laser na filastik na iya rage wahalar masu zanen kaya don tsara samfuran.

A halin yanzu, da yawa kayayyakin (ciki har da mota semiconductor masana'antu, Pharmaceutical da abinci masana'antu, da dai sauransu.) da sosai high bukatun ga aiki daidaito da kuma aesthetic bayyanar, wanda ya sa Laser waldi ya zama dole tsari ga samar da wadannan kayayyakin da kuma inganta ci gaba da ci gaban da ci gaban da ci gaban. fasahar walda laser.

Matsakaicin dacewa, yanayin zafin jiki da daidaitawar walƙiya ta Laser, mafi kyawun tasirinsa zai kasance.Yanayin aikace-aikacen walda na Laser ɗin filastik ya bambanta da na walda na ƙarfe, gami da walƙiya na jeri, walƙiya mai daidaitawa, walda mai aiki tare da walƙiya mashin iska.Olay Optoelectronics zai gabatar da waɗannan hanyoyin walda a takaice.

1. Profile walda

Laser yana motsawa tare da layin kwane-kwane na Layer waldi na filastik kuma yana narke shi don haɗa yadudduka na filastik tare a hankali;Ko motsa sanwicin tare da kafaffen katako na Laser don cimma manufar walda.

A aikace aikace, walƙiya kwane-kwane yana da babban buƙatu don ingancin allura gyare-gyaren sassa, musamman don aikace-aikacen hadaddun layukan walda kamar masu raba iskar gas.A cikin aiwatar da walƙiya Laser roba, kwane-kwane walda zai iya cimma wani takamaiman shigar azzakari cikin farji line, amma wannan shigar azzakari cikin farji ne karami da kuma uncontrollable, wanda na bukatar cewa nakasawa na allura gyare-gyaren sassa bai kamata da girma da yawa.

2. Daidaitaccen walda

Laser katako daga mahara diode Laser an tsara ta da na gani abubuwa.Ana jagorantar katako na Laser tare da layin kwane-kwane na Layer walda kuma yana haifar da zafi a cikin kabu na walda, ta yadda duk layin kwane-kwane ya narke kuma yana haɗuwa tare a lokaci guda.

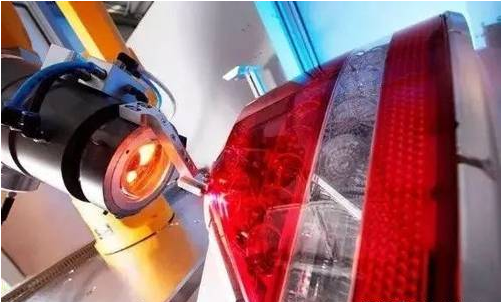

Ana amfani da walda ta aiki tare a fitilun mota da masana'antar likitanci.Walda na aiki tare da katako mai yawa, siffa ta gani yana nuna haske ta wurin waƙar walda, wanda ke da alaƙa da rage damuwa na ciki.Saboda buƙatun suna da girma kuma farashin gabaɗaya ya yi girma, ana amfani da shi sosai a cikin jiyya.

3. Ana duba walda

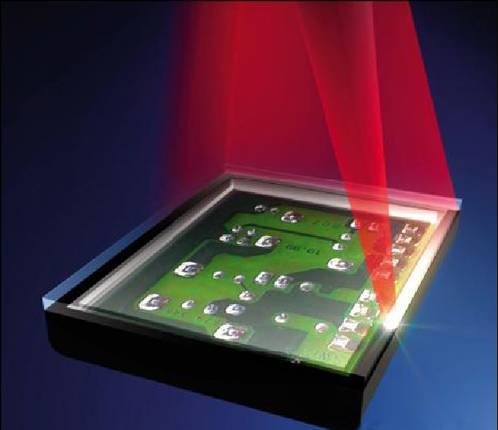

Hoton walda na Laser scanning

Ana kuma kiran walda walda ta quasi synchronous waldi.Fasahar walda ta bincika tana haɗa waɗannan fasahohin walƙiya guda biyu na sama, wato, walƙiya mai ɗabi'a da walƙiyar aiki tare.Ana amfani da na'urar hasashe don samar da katako mai sauri na Laser tare da gudun mita 10 / s, wanda ke tafiya tare da sashin da za a yi wa walda, yana sa dukan ɓangaren walda a hankali ya yi zafi tare da fuse tare.

Quasi synchronous waldi shine mafi yawan amfani.A cikin masana'antar sassa na motoci, tana amfani da galvanometer mai girman mitar XY a ciki.Jigon sa shine sarrafa rugujewar waldar filastik na kayan biyu.Waldawar kwane-kwane zai haifar da babban damuwa na ciki, wanda zai shafi rufe abubuwa.Aiki tare na Quasi yanayin dubawa ne mai sauri, kuma tare da sarrafawa na yanzu, yana iya kawar da damuwa na ciki yadda ya kamata.

4. Mirgina walda

Misalin walƙiya na birgima na Laser

Rolling walda wani sabon tsarin walda na filastik Laser, wanda yana da nau'i daban-daban.Akwai manyan nau'ikan walda na birgima:

Na farko shine walda ball na Globo.Akwai ƙwallon gilashin matashin iska a ƙarshen ruwan tabarau na Laser, wanda zai iya mayar da hankali kan Laser kuma ya matsa sassan filastik.A cikin aikin walda, ruwan tabarau na Globo yana motsa shi ta hanyar dandalin motsi don kammala walda ta hanyar birgima tare da layin walda.Dukkan tsari yana da sauƙi kamar rubutu tare da alkalami na ballpoint.Tsarin walda na Globo baya buƙatar haɗaɗɗiyar na'ura ta sama, amma samfurin tallafi na ƙasa kawai.Tsarin walda ball na Globo shima yana da bambance-bambancen tsarin walda na abin nadi.Bambance-bambancen shine cewa ƙwallon gilashin a ƙarshen ruwan tabarau an canza shi zuwa ganga gilashin silinda don samun ɓangaren laser mai faɗi.Nadi nadi waldi ya dace da fadi waldi.

Na biyu shine tsarin waldawar TwinWeld.Wannan aikin waldawar laser na filastik yana ƙara abin nadi na ƙarfe zuwa ƙarshen ruwan tabarau.A lokacin aikin walda, abin nadi yana danna gefen layin walda don waldawa.Amfanin wannan tsarin waldawar Laser na filastik shi ne cewa ba za a sa ƙafar karfen latsawa ba, wanda ya dace da samar da manyan sikelin.Koyaya, matsa lamba na abin nadi yana aiki akan gefen layin walda, wanda ke da sauƙin haifar da juzu'i da ƙirƙirar lahani iri-iri.A lokaci guda, saboda tsarin ruwan tabarau yana da ɗan rikitarwa, yana da wahala don shirye-shiryen walda.

5. Hasken walƙiya mai walƙiya

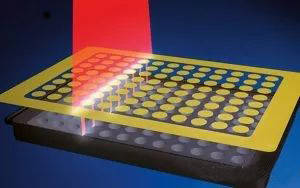

Zane-zanen walƙiya na saka iska mai iska Laser

Ana sanya katakon Laser ta hanyar samfuri don narke da haɗa filastik.Samfurin yana fallasa ƙaramin madaidaicin ɓangaren walda a kan filastik ɗin da ke ƙasa.Hasken Laser kawai yana dumama ɓangaren samfurin wanda abin rufe fuska bai rufe shi ba.Ana iya amfani da wannan fasaha don cimma daidaitaccen walda wanda bai kai microns 10 ba.

Abubuwan microfluidic na iya zama daidai kuma a daidaita su ta hanyar ka'idar walda ta abin rufe fuska.Geometry na tashar zai kasance iri ɗaya, yana guje wa kwararar narkewa zuwa cikin kunkuntar tashoshi mai tsayin mita 200 kawai.

Lokacin aikawa: Oktoba-21-2022